We designed small and portable desalination water system treatment equipment, the flow rate is from 500L/D to 6000L/D, which is very popular. It is also suitable for high salinity groundwater, river water or well water. The characteristics of this kind of seawater reverse osmosis system are small size, compact structure, easy to operation and maintain, easy to move (wheel optional), durable, low noise, etc. , according to the appropriate circuit capacity and motor power, we divide such seawater desalination ro system into brackish water type and seawater desalination type; the whole seawater desalination system is composed of raw water pump, multi-media filter, reverse osmosis main part and cleaning PE water tank , the performance specifications are roughly as follows:

Power consumption: 1.5KW-3KW

Influent TDS : ≤38000mg/L

Product water TDS : ≤600mg/L

Working pressure: 1000PSI (60bar)

Inlet pressure: 1bar

Working temperature: 10-45 ℃

Inlet SDI: ≤5

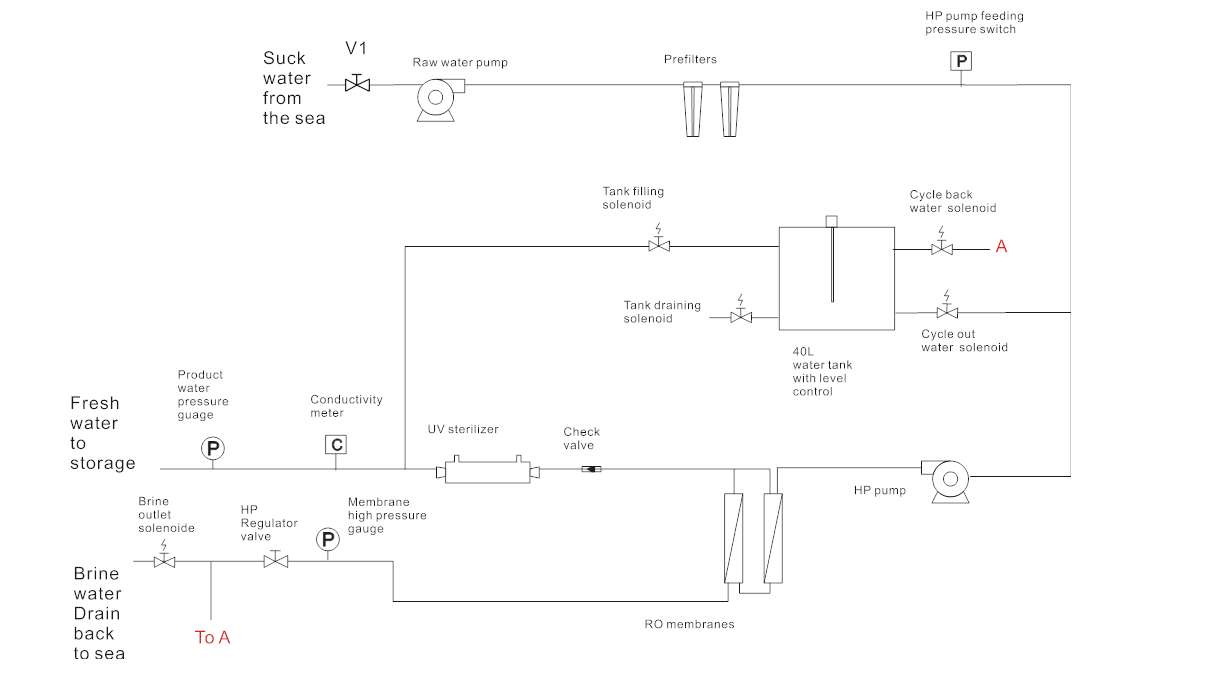

Flow Chart

Sea Water RO System Maintain

The necessity of chemical cleaning and clean water cleaning

When operating a reverse osmosis desalination plant, the separated mineral ions, metal salts, microorganisms, algae, colloids and other impurities will accumulate on the membrane surface and then cause RO membrane fouling, which will result in less flow, or a drop in salt rejection, at any time , if the purified water flow drops to the rated standard (under the same conditions), or the purified water salinity increases significantly, it means that the membrane needs to be cleaned; the reasons for membrane fouling are complex, and the fouling characteristics and pollutants may be different, replace In other words, insufficient operating pressure, or a drop in pump flow will result in a drop in net water flow. So, in order to get an appropriate method to solve this problem, the user should analyze the reasons;

The most common contamination comes from microorganisms, organic matter, and algae in the sea. Monthly cleaning is required to recover from this type of contamination.

Tabel 1: list the character for common RO membrane pollutions

Pollution Reason Metal oxides(Fe,Mn,Ni,Cu) | Common reason | ||

| Salt permeate rate | Membrane pressure loss | Freshwater productivity | |

| Double up rapidly | Double up rapidly | Decrease 20-25% | |

| Sediments (CaCO3, MgCO3) | Increase 20-25% | Increase 10-25% | Decrease <10% |

| Colloid (Silicon colloid) | Double up gradually | Double up gradually | Decrease ≥50% |

| Microbiology (Germs, algae) | Double up | Double up | Decrease ≥50% |

1. Safe cleaning routines and cleaning steps for sea water purification system.

(1). Safe cleaning routines

a. Before use any chemical dose mentioned at the follow charters, be sure to follow the experience that stated here, and claim the detail operation instruction from the dose supplier or the professional.

b. While prepare the protecting liquid, be sure stir the solute to dissolved totally and equally.

c. Use the freshwater without free chlorine to flush the membrane, the water temperature should not be less than 20℃. The permeated water from the membrane or the water after pre-filtration from a non-rusty pipe can do.

d. Before return to normal running, be sure to flush the system under no pressure for about 5 minutes, and then release the freshwater of the initial 30 minutes when the machine begins working.

e. There is a water temperature limit on cleaning, if the PH of the water is 2-10, the temperature should be lower than 40℃, and if 10-11, should lower than 35℃, and if 11-12, should lower than 30℃, please keep the cleaning liquid over 15℃, otherwise the cleaning time could be too long.

2. Cleaning and protection chemical dose use instruction for seawater desalination system

Cleaning dose operation

1. flush the water tank with fresh water at 40~45℃ for 5-10 minutes, till the water turn clean.

2. Add fresh water into the tank, at 40~45℃, add alkaline cleaning dose, density at 0.5%~1%, control the PH value at 11-12, cycle for 40 minutes.

3. flush plant with freshwater at 40~45℃ for 10 minutes, till the water be neutral.

4. Add fresh water into the tank, at 40~45℃, add acid cleaning dose, density at 3%, cycle for 15 minutes.

5. flush plant with freshwater at 40~45℃ for 10 minutes, till the water be neutral.

Chemical dose and water dose should be used as followed table:

| 50 Liter water | acid liquid 500 ml | Alkaline powder 0.5kg | Protection liquid 1000 ml |

Protection dose operation

Add fresh water into the tank, at normal temperature, add protection liquid, density at 1-2%, cycle for 15-30 minutes, keep the liquid inside the system.

Caution: Either the desalination rate or product water flow rate decrease over 15%, the plant should be cleaned immediately, otherwise the life and the plant capacity cannot be recovered any more.

3. PLANT MAINTAINENCE

(1). Keep the reverse osmosis desalination plant clean, wipe off the oil stain or splashed seawater

(2). Fasten the screw or change the sealing if leakage is found between the pipes

(3). Clean or change the precision filter cartridges

a. After running the reverse osmosis desalination plant for some time, the pre-filter cartridge could be stuffed by the impurities in the seawater, this will affect the feed water pressure loss, or feed water flow rate decrease, then could lead to low fresh water productivity. When the reading of the feed water pressure gauge less than 0.1 Mpa , that means the precision filter need to be cleaned or replaced.

b. When replace the cartridge, screw off the housing with the plastic wrench come with the package, put the old cartridge out, and install the new one, and then screw the housing back.

c. The stuffed cartridge can be recovered by dipping it into caustic soda liquid of 5-8% density, for about 6 hours. then flush it with fresh water, then airing to dry.

4. TROUBLE SHOOTING