How Does Reverse Osmosis System Work?

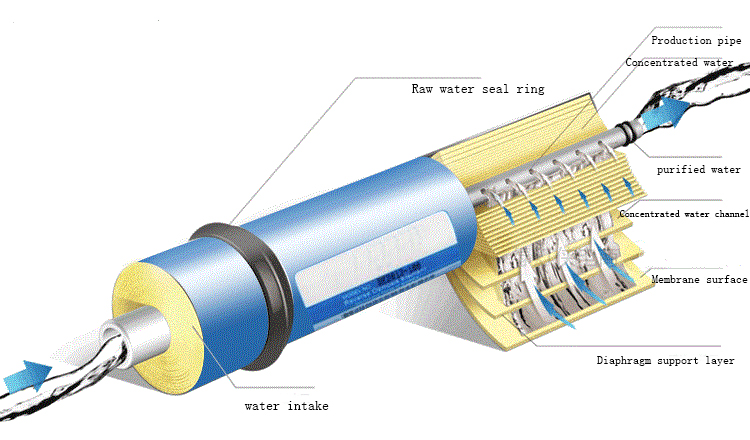

Reverse osmosis membranes are membranes with selective permeability. When liquid or gas passes through the reverse osmosis membranes, some components pass through while others are intercepted. In fact, reverse osmosis membranes are permeable to any component except at very different rates. During the reverse osmosis process, the permeability of the solvent (water) is much higher than that of the solute (salt) dissolved in water. Solvents and solutes are separated by reverse osmosis membrane to obtain pure water and concentrated salt solution.

Water in operation of reverse osmosis flows to the side of the salt solution through osmosis until a new equilibrium is reached. Apply an additional pressure on the side of the salt solution equal to the reverse osmosis pressure. External pressure will increase the chemical potential on one side of the salt solution, causing the solution to flow to the side of pure water. This phenomenon is called reverse osmosis.

There are two ways for water to pass through the membrane, one is through the pores on the membrane, and the other is through the diffusion between the molecular nodes in the membrane. According to the theory, the chemical property of the membrane is that on the solid-liquid interface, water is preferentially adsorbed and passed through, and salt is intercepted. There is a weak chemical binding force between water and the membrane surface, so that water can be dispersed in the membrane structure. The physical and chemical properties of the membrane determine the structure of water than salt in the transfer process.

(1) Yielding water – osmotic solution

The permeate of reverse osmosis and nanofiltration membranes is purified water, so they are also called system yielding water.

(2) Concentrated Water – Concentrated Liquid

Solutions that do not penetrate the membrane are concentrated in the raw water. Concentrated water is discharged as wastewater in water treatment reverse osmosis system.

Applicaiton Of Reverse Osmosis System

At present, reverse osmosis system, as the main desalination process, has been widely used in many fields, including oil, power, chemical industry, pharmaceuticals, drinking water.

| Types of membranes | Feature | Purpose |

| Ultra low pressure flux membrane | Ultra low operating pressure, higher water flux, but low desalination rate | Low salt water |

| Low pressure reverse osmosis membrane | High desalination rate and low water flux | Brackish water |

| Low pollution reverse osmosis membrane | Surface electrical neutrality, good hydrophilicity and strong anti-pollution ability | Surface water |

| Positive charge reverse osmosis membrane | Positive charge on surface, higher cation removal rate | Cation removal |

| Seawater desalination membrane | Super compaction resistance for use in high pressure systems | Seawater desalination |

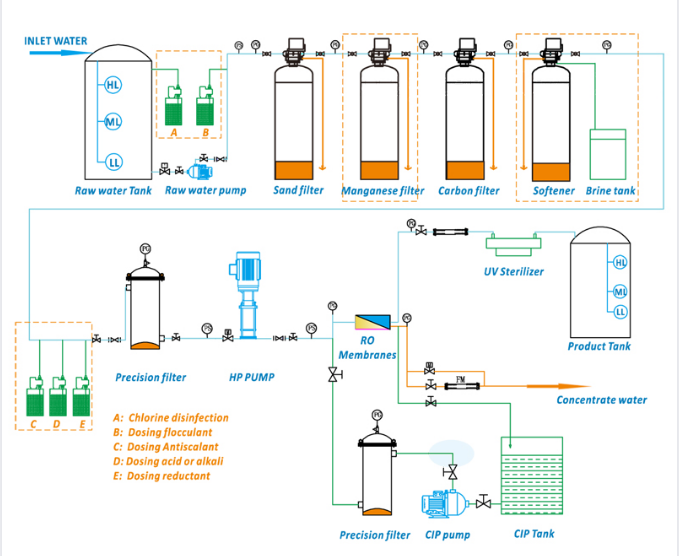

Necessity of Reverse Osmosis Pretreatment

Various raw water contains suspended and soluble substances of certain concentration. Suspension is mainly composed of inorganic salts, colloids, microorganisms, algae and other biological particles. Soluble substances are mainly soluble salts (such as chlorides) and insoluble salts (such as carbonates, sulphates and silicates) metal oxides, acids and bases.

During the reverse osmosis process, the volume of influent decreases and the concentration of suspended particles and soluble substances increases. Suspended particles deposit on the membrane, blocking the flow path and increasing friction (pressure drop). Difficult to dissolve beyond its saturation limit is that it will precipitate from concentrated water, form scaling on the membrane surface, reduce the flux of RO membrane, increase the operating pressure and pressure drop, and cause the degradation of yielding water quality. This deposition on the membrane surface is called membrane fouling, which results in a deterioration of system performance. Need to enter reverse osmosis in raw water.

The effect of pretreatment of raw water reflects that the absolute values of water quality indexes of pollutants such as TSS, TOC, COD, BOD, LSI and iron, manganese, aluminium, silicon and barium are reduced.

Another important water quality indicator of membrane fouling tendency is SDI. Through pretreatment, besides reducing the above indexes to the water requirement range of reverse osmosis system, it is also important to minimize SDI and the ideal SDI (15 minutes) value should be less than 3.

In order to control biological pollution, it is necessary to reduce the dead water area on the pipeline and avoid the use of carbon filters. Before RO membrane loading, the pretreatment system and RO device shall be disinfected. After startup, it shall be kept in continuous operation, and biofilm will grow during shutdown.

The methods to control microbial pollution include: continuous or periodic use of disinfectants online or offline. Effective disinfection and cleaning methods shall be available after biological pollution of RO.

Composition of reverse osmosis system

It includes process flow, membrane module and shell, high-pressure pump, pressure protection, low-pressure flushing, excessive discharge and system detection.

What is the function of high-pressure pump?

The selection of pressure and flow of high-pressure pump system is mainly based on the simulation calculation results of running Hyde energy design software imsdesign.

The selection of high-pressure pump is generally considered according to the condition after three years of membrane operation.

In order to ensure the safety and reliability of the system, the lift and flow specifications can be increased by 10% based on the recommended selection of the calculation results.

Manual regulating valve is generally installed at the outlet of high-pressure pump. The pressure required by the system in the initial stage of operation is smaller than that after three years, so manual regulating valve is used to regulate the output of the pump.

What is low pressure flushing?

Reverse osmosis shutdown automatic membrane flushing. Ro automatically flushes the reverse osmosis membrane when the system is shut down to avoid dirt deposition.

How to operate over standard emission?

Excessive discharge / shutdown / alarm of pure water quality

When the conductivity of pure water exceeds the maximum allowable value, the reverse osmosis system will shut down automatically and give corresponding alarm signals.

Pressure gauge: pre membrane pressure, inter membrane pressure and post membrane pressure

Thermometer: inlet water temperature

Flow meter: produced water flow, concentrated water flow

Conductivity meter: water inlet conductivity, water production conductivity

Common problems

When the water production decreases

(1)Changes in the following parameters will reduce the actual water production of the membrane in the system

(2)When the pressure of the inlet pump remains unchanged, the inlet water temperature decreases

(3)Reduce RO water inlet pressure with throttle valve

(4)Increase the produced water back pressure when the inlet pump pressure remains unchanged

(5)The influent TDS (or conductivity) increases, which will increase the osmotic pressure that must be overcome when the produced water passes through the membrane

(6)The recovery rate of the system increases, which will increase the average influent / concentrated water TDS of the system, thus increasing the osmotic pressure

(7)Contamination of membrane surface

(8)The pollution of the inlet channel network leads to the increase of inlet concentrated water pressure drop (△ P)

Ocpuritech, the best reverse osmosis system manufacturer in China, provides industrial reverse osmosis system, commercial reverse osmosis system, ultrafiltration system, seawater desalination deionized water system and filter cartridge.