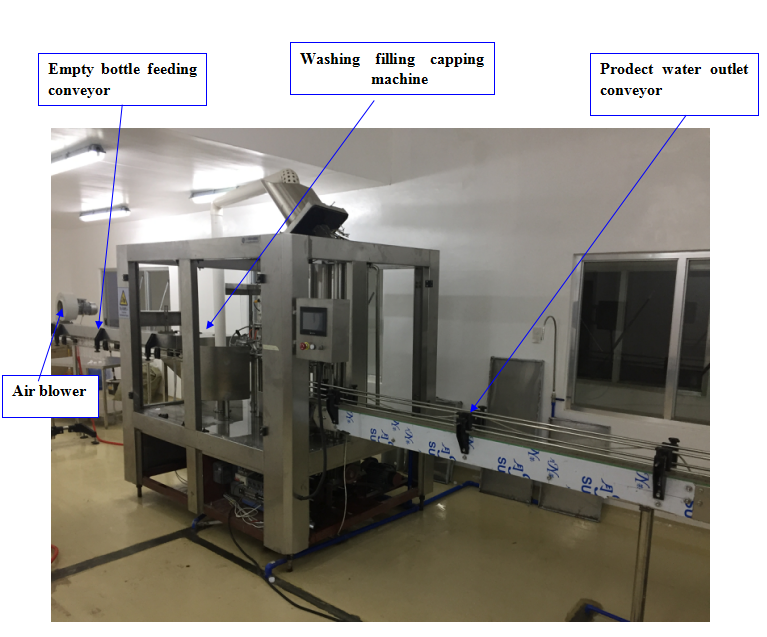

“Monoblock Small Bottle Filling Machine” is a new product in water bottling plant. Higher work efficiency. Use advanced circumrotate working technology, congregate: washing, filling and capping integrative. Machine make of stainless steel, empty bottle use air feeding feeding conveyor, washing bottle, filling water, capping bottle all position working automatic by PLC-control, whole machine designing is reasonable, is convenience to handle. Most consumer like this equipment.

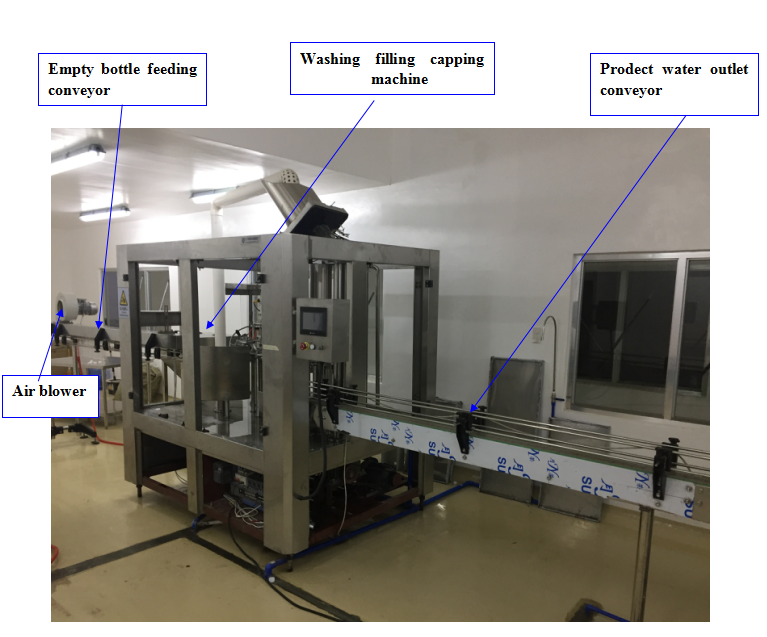

Small Bottle Filling Machine function include: Empty bottle transmission (air feeding) → Auto washing bottle → filling water → capping (Auto working fully all position)

|

Filling capacity

|

2000BPH with standard 350ml bottles

|

||

|

Filling pressure

|

above 0.4 MPa

|

||

|

Input power (KW)

|

3.5KW

|

||

|

Washing position

|

8 positions

|

||

|

Filling position

|

8 positions

|

||

|

Capping position

|

3 positions

|

||

Capacity

2) 1600BPH Bottles with standard 500-600ml bottle

3) 1000 Bottles with standard 1000ml bottle

4) 600 Bottles with standard 1500ml bottle

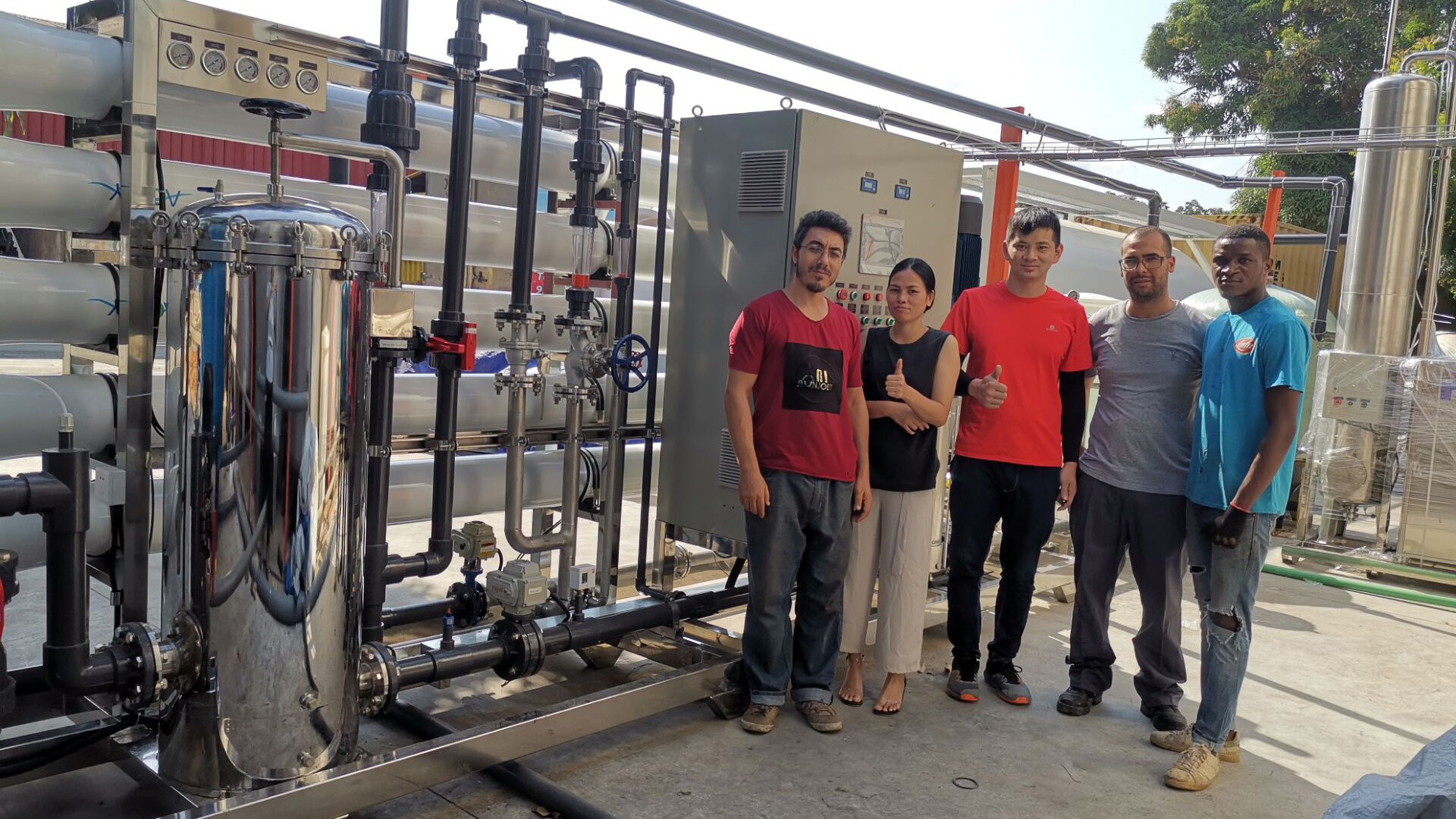

Our Services & Strength

The durable High-impact carton to protect the products.

Lead time for water filter cartridge is 5-7 working

Lead time for the water treatment system is 7-15 working days

Q: Are you trading company or factory?

A: We are factory.

Q: How Does Reverse Osmosis Work?

A: Reverse osmosis systems purify water by forcing pressurized water through a very fine, plastic membrane. If the raw water being treated comes from a well or another private source, disinfection and pre-filters (to remove chlorine and/or particulates/sediment) may be needed in advance of the R/O unit to remove contaminants that can foul or damage the membrane.

Title goes here.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

A high reputation of this product has been formed among manufacturers and users. Ocpuritech??s water system is an economical and convenient choice.