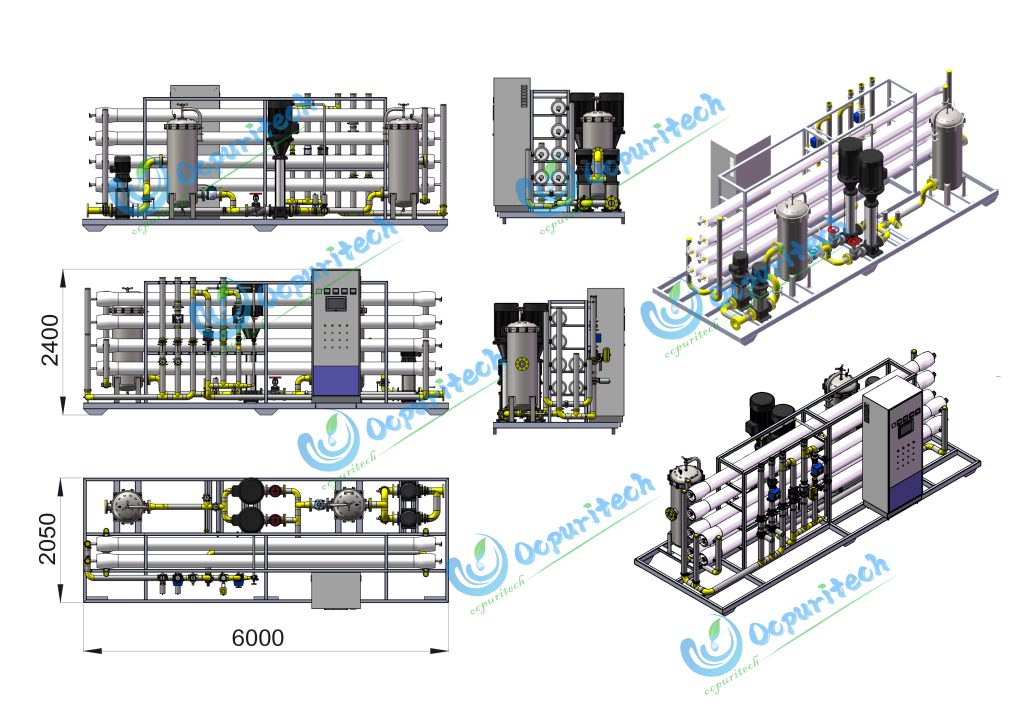

- RO Main Unit:

- Stainless steel precision filters

- High-pressure pump

- 30 pieces of 8040 RO membranes

- Membrane Configuration:

- 30 pieces of 8040 RO membranes

- Housed in 6 fiberglass membrane casings

- Operational Efficiency:

- All pumps operate on a 1-duty, 1-standby basis

- Enables 24-hour system functionality

- Prolongs the lifespan of pumps

- High-Pressure Piping:

- SS316 construction for stability

- Extended lifespan

- Ensures safe, food-grade water

- Cleaning in Place (CIP) System:

- Consists of precision filters and CIP pump

- Regularly cleans RO membranes

- Extends membrane lifespan

- Reduces operational costs

- Siemens PLC Control System:

- 10-inch PLC control system

- Fully automatic and intelligent control

Project Benefits:

- Tailored for the Coca-Cola project in Sri Lanka

- Ensures optimal performance and longevity

- Provides a stable supply of food-grade water

- Reduces operational costs with efficient membrane cleaning

- Fully automated for seamless control and monitoring.

Working process:

Application of RO System