Introduction

The 250lph Reverse Osmosis (RO) system is suitable for applications requiring depth

fltering. More than 99% of all microorganisms, pyrogens, particulates, organics with a

molecular weight greater than 300, and up to 95% of all dissolved inorganic contami-

nants from the feed water are removed.

The 250lph RO system is supplied on a skid consisting of precision flter ,H/P pump, RO

membranes,manifolds, valves, pressure gauges, fowmeters, a control panel and tubing.

The system skid and manifolds are shipped fully assembled, pre-piped and pre-wired.

See System identifcation for detailed description of the system components. The stan-

dard RO system is available in 380VAC(50 Hz) 1phase.

The control panel consists of a digital controller, an electronic digital interface and

display for the RO runing fowchart.

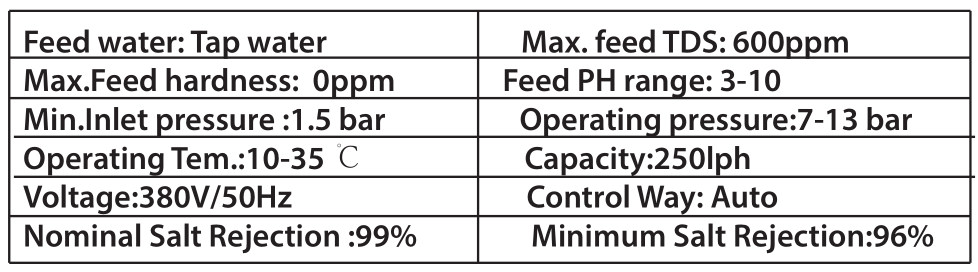

Feed water and operating parameter

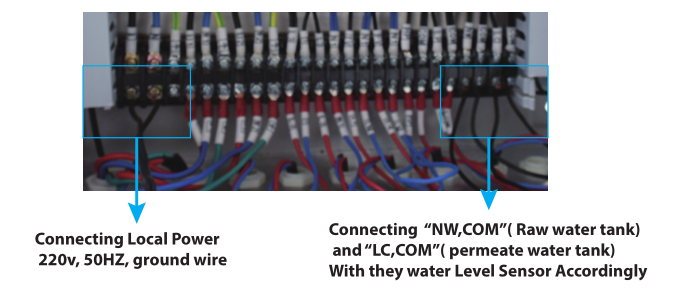

RO electricity connection

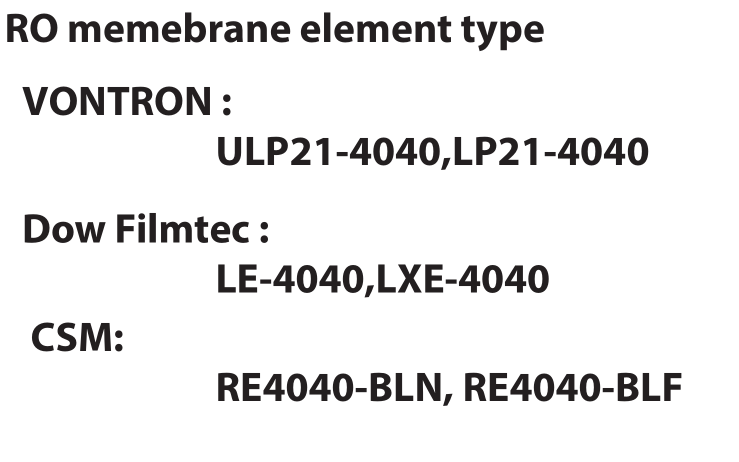

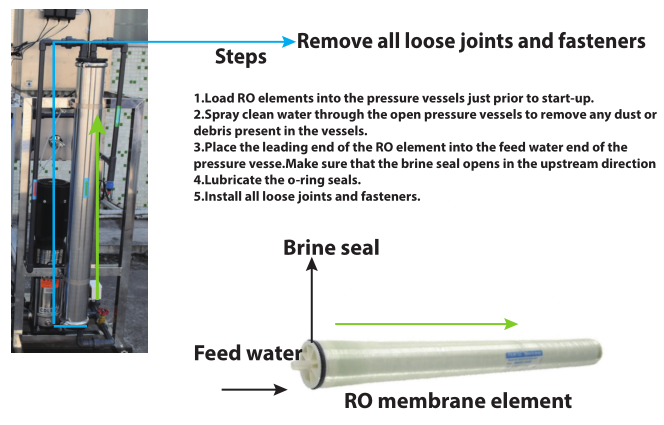

RO Membrane installation

Start-Up and shut down the RO system

Proper start-up of reverse osmosis systems is essential to prepare the membranes for operating

service and to prevent membrane damage due to excessive pressure/fow or hydraulic shock.

Following the proper start-up sequence also helps ensure that system operating parameters con-

form to design conditions so that water quality and productivity goals can be achieved.

1. Start-Up Sequence

1.Check all valves to ensure that settings are correct. Concentrate regulator and inlet valve is fully open.

2. Then switch on “Emergency stop(Power switch)”,“inlet valve ” ,“low pressure pump”to manual status .

3. Slowly open RO inlet regulator valve,use low pressure water at a low fow rate to fush the air out of the

elements and pressure vessels. Flush at a gauge pressure of 30 to 60 psi (0.2 – 0.4 MPa). All permeate and

concentrate fows should be directed to an appropriate waste collection drain during fushing.

4.During the fushing operation, check all pipe connections and valves for leaks. Tighten connections where

necessary.

5.After the system has been fushed for a minimum of 30 minutes, slowly and fully open RO inlet regulator

valve, Switch on “High pressure pump”to manual status ,increasing the feed pressure and feed fow rate to

the membrane elements until the design concentrate fow is reached. The feed pressure increase to the

elements should be less than 10 psi (0.07MPa) per second to achieve a soft start. Continue to send all perme-

ate and concentrate fows to an appropriate waste collection drain.

6.Slowly close Concentrate regulator valve until the ratio of permeate fow to concentrate fow approaches,

but does not exceed, the design ratio (recovery). Continue to check the system pressure to ensure that it does

not exceed the upper design limit.

7.Repeat steps “6” until the design permeate and concentrate fows are obtained

9.After the system to run for one hour,switch the permeate fow from drain to the normal service position.

10.Switch on “inlet valve ” ,“low pressure pump” ,“High pressure pump”to auto status. The system is running normally.

2.Operation Start-Up

Once the RO system has been started up, ideally it should be kept running at constant conditions. Start/stop

cycles result in pressure and fow changes, causing mechanical stress to the membrane elements. Therefore,

the start/stop frequency should be minimized, and the regular operation start-up sequence should be as smooth as possible.

3.Shut down the RO system

1.Make sure RO controlller connect the level sensor.

2.After the permeate water tank is full , the fushing valve will open and fush for 30 seconds!

3. Turn of “Emergency stop(Power switch)”and then the RO system will stop!

Maintenance

1.Filter cartridges, RO membranes replacing:

(1)PP Filter cartridge’s service life mainly depends on raw water quality, but normally they can service for 3

months if the raw water is from tap.

(2)RO membranes normally can service for 2-3 years. If you found the output rate is decreasing or TDS is still

high after chemical cleaning, please replace them.

Our water treatment system have been certificated by CE and provide 1-year warranty, many clients are very recognized for the quality of our products, we are your trusted partners.

1.Provide complete OEM or ODM water treatment solution based on your source water

2.Provide free technical training and full good after service.

3.We have professional QC team to check the quality before delivery

4.Strong carton to protect the products

3.Reply in 24 hours.

5.Lead time for water filter cartridge is 5-7 working days

Lead time for water treatment system is 7-15 working days

Guangzhou Aomi Water Purification System Manufacture Co., Ltd is specialized in a Water Purifier for household and industrial water treatment. Our main products include RO device, Ultrafiltration, Microfilter, sand, and carbon filter equipment, etc. These products completely set of equipment for school, factory, and hospital. Besides, we are manufacturing tap water and mineral water equipment.

We have been devoted ourselves to Water RO System for many years, and our engineers can make different types of water treatment equipment. We have the expertise to manufacture water treatment equipment of different sizes, capacity, and optional functions. And we also provide relative products such as FRP tank, valves, filter cartridge, and membranes, etc. Under our excellent products and patience service, we have earned a great reputation for our product quality, performance reliability, and business integrity.

1.Do you have water analysis report ?

The report can appear your water quality by TDS ,or some metal element content.

2.what is your application of the output water ?

Like direct drinking, industrial use or bottled water.

3.What is the minimum quantity ?

1set/pcs ,If with large quantity ,there will be a special discount or wholesale price.

4.Are you manufacturer or trading company?

We are the Top professional manufacturer in China, more than10 years experience in the water treatment.

</