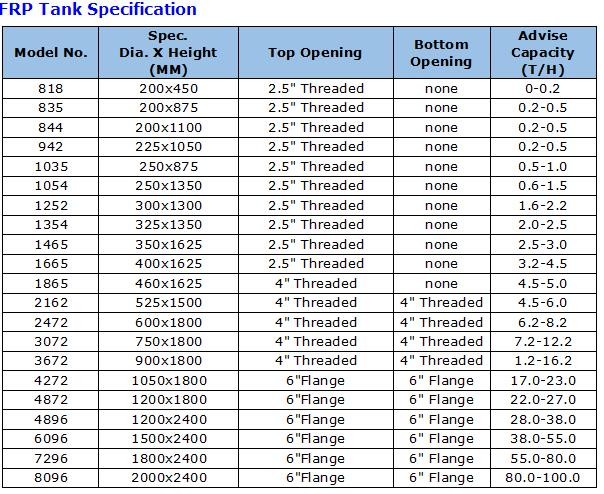

FRP pressure tank description

Our exclusive, patented manufacturing process creates a seamless polyethylene(PE) shell that is wound continuously with fiberglass roving and sealed with epoxy resin. This process results in a corrosion-resistant,leak-free vessel.

Computer-aided winding machines and other customized equipment are used to produce a tank that offers outstanding performance and durability.

The ideal vessels can provide years of reliable service for water conditioning and filtration applications. These slim diameter tanks offer unmatched strength and chemical resistance .Theri allow for multiple plumbing ports on the top and bottom domes as well as the sidewalls.

Pictures Show

FRP TANK PROCESS

OPTIONS

Available in black, blue, or natural

STRUCTURE & MATERIAL

Liner material: PE(polyester) blow molding seemless without leakage

Outer wilding:High perfomance fiber glass and expoxy resin

Base material:PP

OPERATING CONDITION

Max.operating pressure:150psi(10.5 bars)

Max.operating temperature:120°F(49℃)

Max.vaccum;127mm Hg

Working medium:Water, acid, alkali and other chemical corrosive liquid

DESIN PARAMETER

Burst pressure:600psi/42bar

Fitague cycle:100,000

Material Information

FRP tanks with Price75% of the main parts of our products are provided by world famous suppliers.

Applications:

Residential/light commercial softening & filtration

Portable exchange tanks

Features:

100% high performance resin and glass fiber construction

Outstanding performance and durability in harsh chemical environments

Requires little or no maintenance

Factory-backed 1-year warranty

Polyethylene inner shell

In the meanwhile,We produce environmental protection water treatment components with new

type composite materials and offer a great variety of All FRP tanks.All FRP tanks have higher

strength,temperature and pressure capabilities and are NSF certified.

Guangzhou Ocean Environment Protection Technology Co., Ltd consistently deliver water to meet

your requirements.

Packaging Details: The tank under 18″ dia. are packed with paper carton.

21″ dia or larger are packed with PE foaming sheet and paperboard outside.

40″ dia or larger are add with wooden pallt under base.

All FRP tank are placed uprigh standing.

Delivery Detail: 7-15 days after receipt of 30% deposit

Shipping: We will choose the fastest with the cheapest shipping mode for you by air, sea or courier.

We in line with strict production, strict management and strict quality production philosophy. All of our products are double checked before transportation/shipment. If there are some unexpected problems happen, please contact us anytime(by phone,email/message), please provide photos or video and other evidence to seller for checking out the real reasons,so that we can solve it for you asap.

Believe in your vision and choice, we give you the best service and products. Thank you for your cooperation and kind helps.

Any question about our products or us, welcome to contact me anytime.

April Liu

Operators are more focused on their work when applying this product because they do not less likely to wear and tear. By using water treatment system, the reuse of water can be effectively improved.