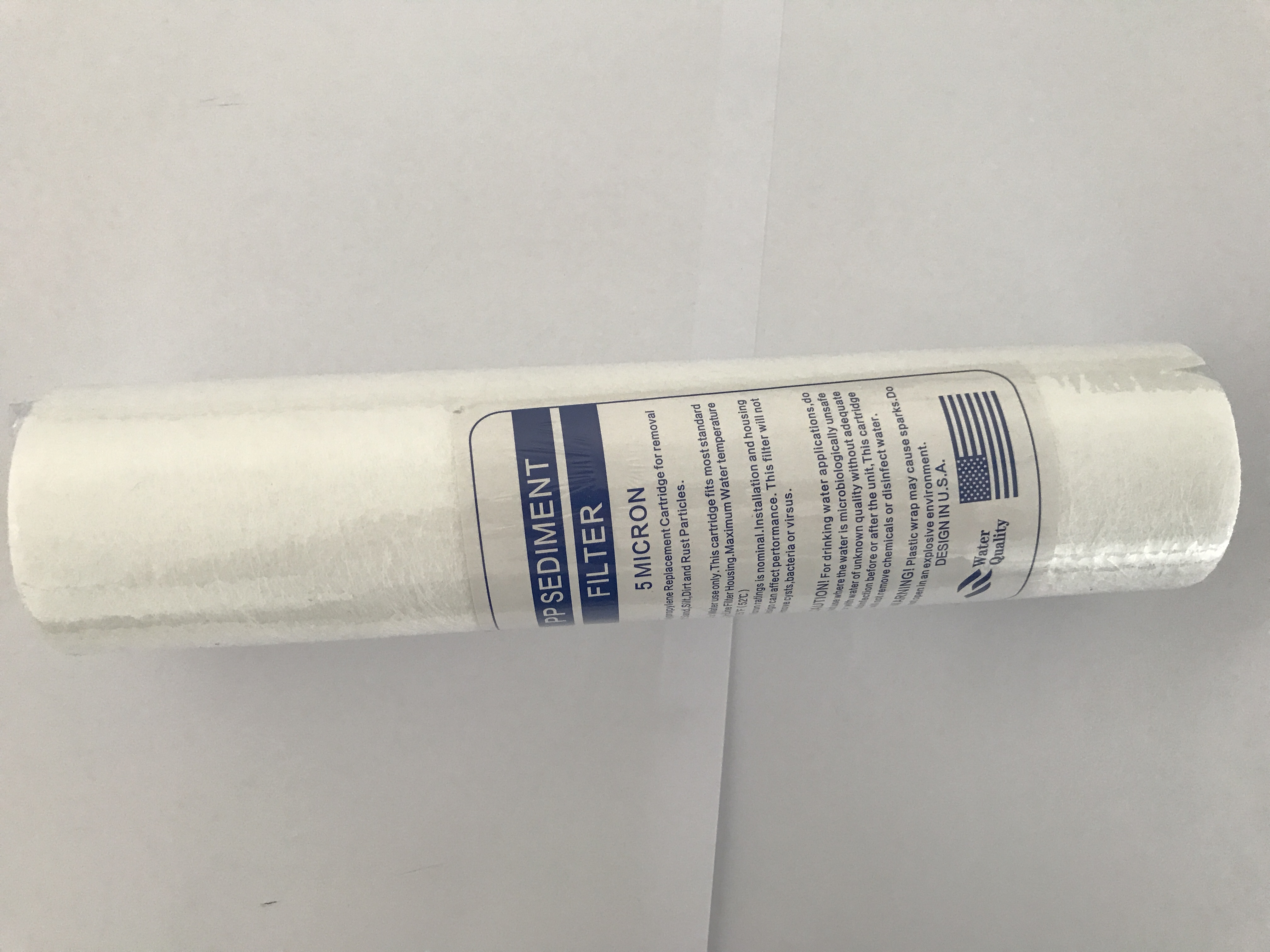

10 inch 5 micron pp melt blown filter cartridge for ro system

PP melt blown filter cartridge use food grade polypropylene as raw material with the process of hot melting spray,spray,traction and winding.

PP melt blown filter cartridge is constructed of loosened layer,compacted layer and precise layer to ensure high efficiency filtration performance.

PP melt blown filter cartridge can remove some impurities like suspended substances,particles and rust effectively.

PP melt blown filter cartridge advantages:

Large flow rate

corrosion resistance

high pressure resistance

low cost

| Cartridge Specification: | |

| Filter design: | Polypropylene |

| Core: | Polypropylene |

| Filter ends: | Not applicable |

| O-rings: | Not applicable |

| Filtration performance: | 5 |

| Dimensions: | |

| Length: | 10”(254mm) |

| Inner diameter | 28mm/30mm |

| Outer diameter | 60mm |

| Max. Application temperature | 60°C. |

| Instantaneous application temperature | 120°C |

| Maximum working pressure: | 10 bar |

| Max. differential pressure pressure: | 0.4 MPa |

Application area

1) Pretreatment for Domestic Drinking water filtration and RO systems.

2) Soda and acid liquid filtration for industrial chemical process.

3) Industrial waste-water, electroplating water filtration.

4) Imaging solution, ink filtration.

5) Pretreatment for Sterile water, ultra-pure water.

6) Chemical raw materials, organic solvent filtration.

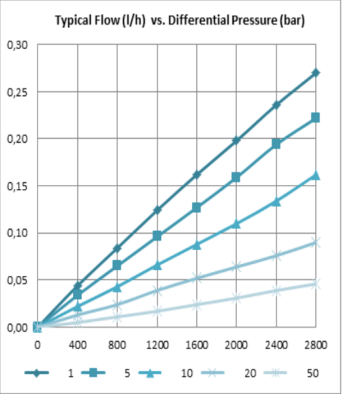

Performance

1) High corrosion resistance and filtration precision since made of 100% hyperfine PP yarn;

2) Low resistance of feed flow: Groove, Pinhole or Embossed structure on surface;

3) Large amount of Permissible Quantity of pollutants since 3 layer Gradient Density structure of the filter;

4) Avoid fiber removal since the Reinforced Fiber Structure on Surface;

5) Safety and available for drinking water: without any Adhesives.

Standard exporting carton package.

50pcs/CTN

Guangzhou Aomi Water Purification System Manufacture Co., Ltd is specialized in a Water Purifier for household and industrial water treatment. Our main products include RO device, Ultrafiltration, Microfilter, sand, and carbon filter equipment, etc. These products completely set of equipment for school, factory, and hospital. Besides, we are manufacturing tap water and mineral water equipment.

We have been devoted ourselves to Water RO System for many years, and our engineers can make different types of water treatment equipment. We have the expertise to manufacture water treatment equipment of different sizes, capacity, and optional functions. And we also provide relative products such as FRP tank, valves, filter cartridge, and membranes, etc. Under our excellent products and patience service, we have earned a great reputation for our product quality, performance reliability, and business integrity.

1.We have professional QC team to check the quality before delivery

2.Strong carton to protect the products

3.Reply in 24 hours.

4.Lead time for water filter cartridge is 5-7 working days

Lead time for water treatment system is 7-15 working days

Our clients

Contact us

Send inquiry to get customized solution

All our warehouse staff are well-trained to move water treatment systems with great care during loading. By using water treatment system, the reuse of water can be effectively improved.